The wing tip halves were glued together and clamped all around the edges to ensure correct registration while the glue set. These seams then required a number of iterations of putty-sand-prime until all traces of the seam had been eradicated. The guns were also glued together and the seams addressed on these too.

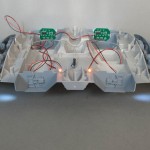

In some shots of the Raider in flight, and on at least one of the studio miniatures, there are additional lights visible on the underside, on the outside of the channels that run from the intakes to the engines – these appear to be mounted in small reflectors recessed into the fuselage. Using a short length of 10mm dia rod, I machined up a couple of these which are glued on the inside of the fuselage and hold a 5mm LED, also driven by the controller PCB.

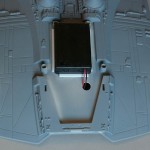

A few strips of styrene were added to the fuselage top to hold the battery box in place – this slips up under the centre console quite happily and the styrene stops it sliding around, but still allow it to be pulled forward for switching on/off and battery changing. A hole was drilled just in front for the wires to pass down into the electronics inside.

When the 2 halves of the fuselage are placed together, the small “V” tabs on the top half are quite badly out of alignment with the bottom, protruding a couple of mm at the ends. The wingtip sides cover most of the rear tabs, but the front ones remain visible. I decided to cut these tabs off the top half completely, and then just fill in the gap on the bottom half with some plastic card – it was far easier this way to get the whole thing flush and smooth.

Whilst waiting for some other bits to set, I decided to start doing a bit of pre-shading of the panel lines with black over the grey primer coat. This looks quite extreme but once the top coat goes on, most of it will having been covered up again, leaving just a hint of depth.

A quick final test of all the lighting in place