One of the examples I made up for the original V1 LED driver was a police car lightbar to fit a 1/24th car kit (The one I had was an Lindberg Ford Crown Victoria). Whilst the PCB with the LEDs on fitted inside the clear cover of the kit, the driver board was way too big to be hidden anywhere in the car, and also required 5 wires to connect to the light board.

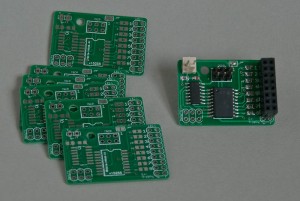

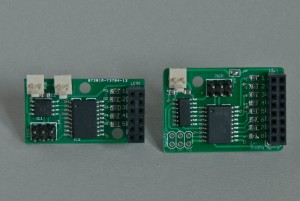

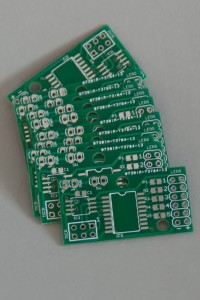

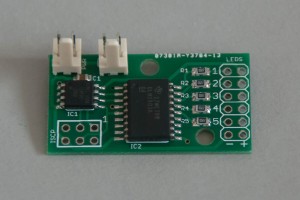

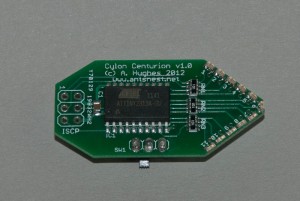

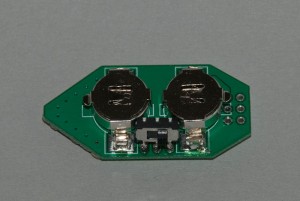

Having played around with surface mount components and various other Atmel microcrontrollers for a while I decided to see if I could get a complete driving circuit onto just the light board. An Tiny85 in a SOIC package was small enough to fit in the center of the board, and provides the 4 ouput ports required to drive the LEDs. It will run happily on the 8MHz internal oscillator, so no additional timing components are required, and will also run on 3v. A single CR2032 will power the board for a few hours and can very easily be hidden within the kit, or for a more longer lasting supply either 2 AAA’s or a single lithium CR123 will run it for much longer at the expense of a little more bulk.

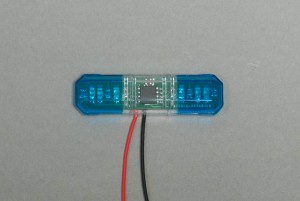

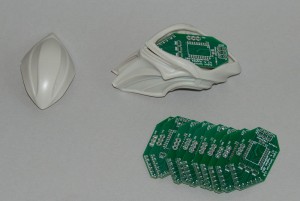

Lightbar PCB inside kit cover

Lightbar in action