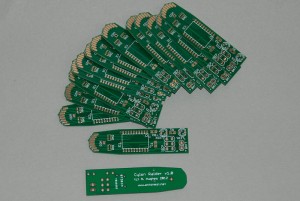

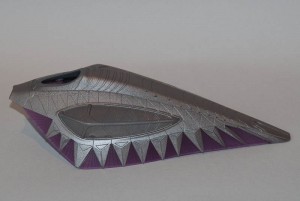

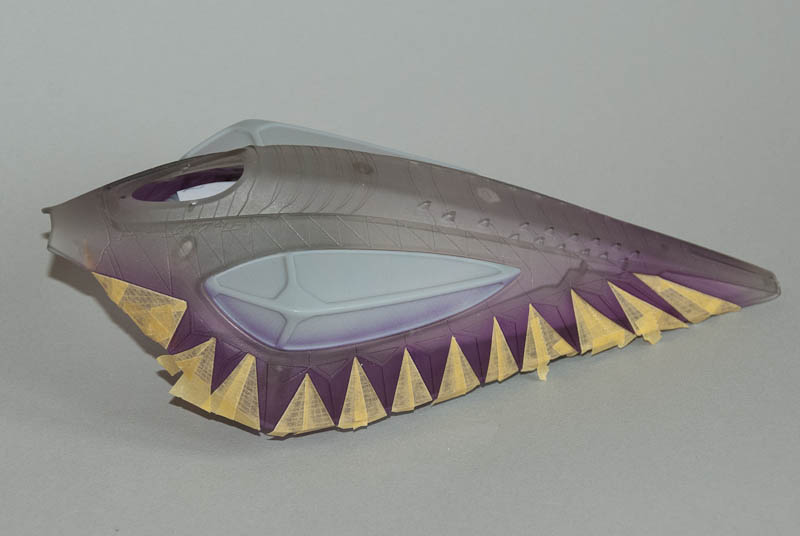

While I wait for the first batch of PCBs to be manufactured, I’ve started work on the engines and how I’m going to mount the LEDs inside them. Given these will be high brightness types, light leakage through the plastic can be a problem, even when painted. The best approach is to use something totally opaque on the inside of the parts. Kitchen foil fits the bill nicely and it will help reflect the light around the inside of the engine.

I glued a small piece of foil into each engine half with PVA, making sure it was burnished into all the corners and then trimmed off the excess once it had dried. I also made a couple of small bulkheads to go into the back of the engines – I used the kit pieces as a template to draw onto some 0.5mm styrene and then sanded them to fit inside snugly. A 5mm hole was drilled in the centre of each for the LED to poke through.

Handy tip – it’s really hard to drill neat holes in thin styrene without the drill bit snagging if you are doing it by hand, or the styrene melting from friction heat if using a hobby drill. In this case I drilled a small (1.5mm) pilot hole and then used a tapered reamer to enlarge the hole by hand until it was exactly the right size for a snug push fit.

A strip of the foil was removed at the back of the engine so the bulkhead could be glued in place. The two engine halves were then stuck together and allowed to dry. There was still a bit of light leakage along the seams so an extra strip of foil was glued in on each side to cover these.

The bulkheads were secured fully in place with an extra bit or 5 min epoxy (you don’t want to push them out when fitting the LEDs later!) and then the area behind them was painted black – any excess light out the back needs to be blocked. I shall probably cover over the back ends completely one the LEDs are fitted.

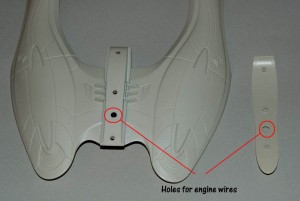

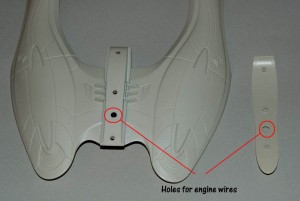

The wires for the LEDs need to come down from the module in the head – I drilled a 6-7mm hole through the body section and the underside head plate midway between the two rear mounting lugs on each to ensure the holes matched. From here you can feed the wires down to the back of the engines without further surgery.

I still need to think how / where to extract the battery wires. I’ve thought about a 2mm power plug/socket arrangement and a new base, but it would be nice to use the original stand too. Does it really need to be removable? Makes packing for shows easier, but it’s not the end of the world. I could run a couple of strands of wire-wrap wire down the back of the stand arm, and even fit a single 3V CR123 sized cell under the base… Food for thought.