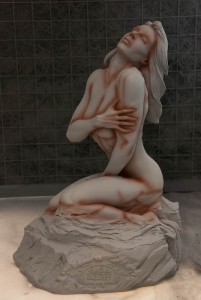

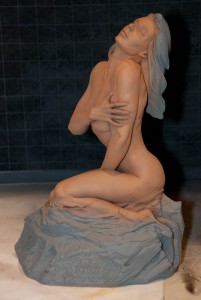

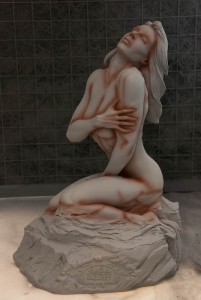

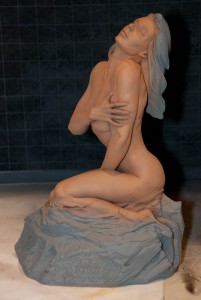

I’ve had this kit for about 10 years. It’s based on a painting by fantasy artist Julie Bell called “Ecstasy” and was sculpted and produced by Steve West of Cellar Cast to compliment their range of other kits from artwork by Boris Vallejo (Julie’s husband).

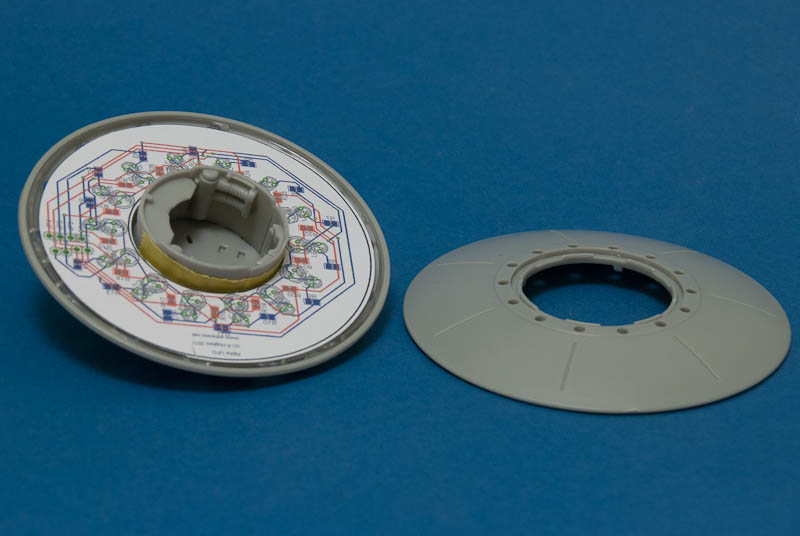

Despite the good heritage of being a Cellar Cast kit, it’s been one of those that’s been in and out of the cupboard many times due to some manufacturing issues – most notably a proliferation of tiny airholes all over the rocky base. Over the years I’ve tackled them again and again, seeming to make no progress. They are small enough to be difficult to fill with putty, but large enough to still be seen. I’ve tried, epoxy putty, acrylic paste, opening them up larger and then finally just going a bit mad with a milling bit in the drill, hacking and carving away large areas of offending bubbles.

As it turns out, this was the best approach – given the very fractured rock texture of the base, you really cannot see what is original and what I’ve had a good old go at! I wish I’d just done it years ago…

The other problematic area was the hair – airholes in all the strands were much harder to repair, and for this I just had to be patient. Putty, sand, prime, rinse, repeat. it’s still not perfect but I got to the point where I had to start getting some paint down or the whole thing was going out the window…. There are still many holes in the lettering of the nameplate, but I’ll cross that bridge when I come to it.

On with the paint. Priming was the ubiquitous Halfords grey – I dread to think how many cans of this I’ve bought over the years, but I’ve yet to find anything better for the cost. Having said that, it has been reformulated in the last couple of years and now has a much grainier finish than it used to.

There are quite a few deep recesses in this figure that will be hard to get the airbrush into. I started off with a chestnut brown pre-shade into all the folds and crevices, making sure that all the grey was covered when viewing from any angle. Nothing worse than getting most of the way through a paint job and finding you’ve missed a bit. It’s then much easier to go over the brown with you flesh colours, and any of the bits you can’t reach will have a natural shading anyway.

After that, a base coat of Miniature Paints Tanned Flesh – this is my favourite out of the bottle flesh colour. Most seem to be either too pink, or too orange, this one is just right.

A darker shade was mixed up with a bit of Chocolate Brown and this was lightly applied around all the edges of the skin and into the shadows & folds. The base flesh was then lightened with a drop of white and applied to all the natural highlights of the figure – all those upper surfaces where the light falls directly. It sometimes takes a few iterations of dark & light until you are happy with the overall effect.